Ergonomic Design of Teacup Handles sets the scope for this exploration. This phrase anchors discussion of comfort, grip mechanics, and user safety. Designers and engineers consider hand size, wrist angle, and thermal transfer together. Research in human factors guides handle geometry for varied populations. In daily use, a teacup handle must balance ease of lift with confident control. Materials and surface texture influence slip resistance and tactile feel. Prototyping with rapid iterations reveals small but meaningful improvements. Clinical users and elderly drinkers often benefit most from intentional handle design. This opening frames why teams should prioritize ergonomics early in teacup development cycles.

Principles of Human-Centered Grip

Ergonomic Design of Teacup Handles relies on human-centered grip principles. Hand anatomy drives recommended ring size and clearance for fingers. Designers measure span across fingers to set loop dimensions that minimize strain. Grip posture affects wrist torque and shoulder tension during lifting. Rounded edges and smooth fillets reduce pressure points on the finger pads. A balanced center of mass lowers torque on the wrist when a cup contains liquid. Thermal insulation in the handle prevents heat transfer without bulky bulk. Rapid user trials with diverse age groups reveal preferred clearance and loop orientation. Applying these principles reduces discomfort and increases daily usability for many users.

Handle Geometry and Its Effect on Pouring Control

Handle geometry matters for pouring accuracy and spill avoidance. Wider loops distribute force across multiple fingers. Narrow loops concentrate pressure at a single phalanx and may cause fatigue. Angled handles align the wrist with pouring trajectories for smoother transfer. Offset handles improve visual sightlines when bringing the cup to the lips. Designers also account for thumb placement to stabilize lateral motion. Symmetry in handle design supports both left and right-handed users in many cases. Small lip radii at contact points can prevent blistering under repetitive use. Prototypes tested with weighted pours show measurable reductions in spillage when geometry matches common grip styles.

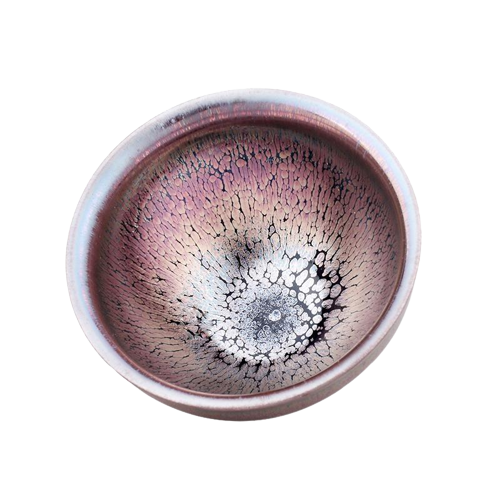

Material Choices That Influence Tactile Feedback and Safety

Material selection influences tactile feedback and long-term safety in handle design. Porcelain provides a crisp, cool feel that many users prefer for ritual drinking. Some ceramics incorporate microtexture to boost slip resistance without affecting aesthetics. Thermally insulating composites reduce heat transfer and protect fingers during hot infusions. Silicone overmolds supply high-friction contact areas for users with reduced grip strength. Recycled materials can achieve both tactile and environmental goals when properly processed. Surface finishes matter; glossy glazes may feel smooth but become slippery when wet. Material tests under wet conditions and soapy residues identify optimal surface treatments for safe handling.

Thermal Management and Heat Transfer Considerations

Thermal management is central to comfortable teacup use. Handles must isolate heat while remaining compact and elegant. Hollow handle sections create insulating air gaps that slow conductive transfer. Low-conductivity materials such as certain polymers and composites add protection without bulk. Some designs use a thin insulating coating to avoid altering the cup’s visual language. Designers must also consider heat buildup under prolonged exposure to hot water. In lab testing, insulated handles reduce skin surface temperature significantly during standard steep cycles. Clear thermal criteria in technical specifications help manufacturers meet comfort thresholds reliably across production batches.

Accessibility and Inclusive Design for Diverse Users

Inclusive design expands teacup usability across ages and abilities. Larger loop diameters suit users with arthritic hands or limited dexterity. Textured grip pads and color-contrast cues help those with visual impairment. One-handed stabilization features allow users with a single functional hand to lift cups safely. Modular handle inserts enable retrofitting existing vessels for improved ergonomics. Regulatory guidance for accessible products should inform early design decisions. Field trials with eldercare centers or rehabilitation clinics produce actionable feedback. Prioritizing accessibility increases market reach and demonstrates social responsibility in product development.

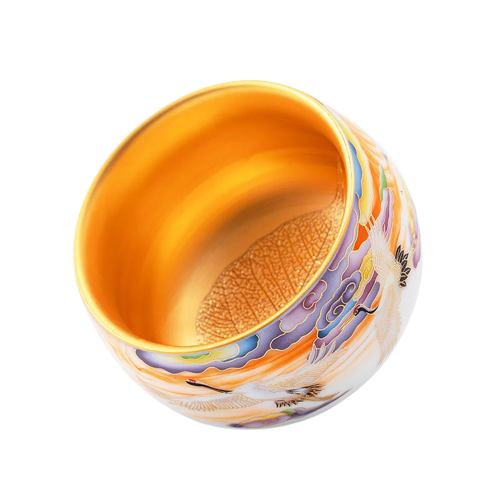

Aesthetic Integration: Balancing Form and Function

Aesthetic integration ensures teacup handles appeal visually while performing well. Designers often fuse sculptural lines with ergonomic fillets to achieve harmony. Proportions must respect the cup’s overall silhouette to avoid awkward balance. Surface treatments provide both tactile benefit and visual richness when chosen carefully. Many premium brands use subtle texture contrasts to signal grip areas without breaking the form. Color and pattern can highlight handle ergonomics by guiding finger placement. Collaboration between industrial designers and ceramicists preserves both function and craft sensibility in final products.

Prototyping Methods: From CAD to Physical Mockups

Rapid prototyping accelerates validation for ergonomic handle designs. Digital models in CAD capture exact loop dimensions and stress points. Finite element analysis predicts deformation under typical loads. 3D-printed mockups give quick tactile feedback without full production costs. Clay or resin casts reproduce weight and surface feel closely for final evaluation. User sessions with timed tasks record subjective comfort and objective metrics like lift angle. Iterative cycles reduce the risk of mass-producing an unpopular geometry. Clear documentation of each iteration supports scale-up and preserves design intent for factory handover.

List of Key Ergonomic Design Guidelines for Handles

-

Ensure loop clearance fits multiple finger sizes.

-

Use rounded fillets to reduce pressure points.

-

Position handle angle to align with natural pouring motion.

-

Specify thermal insulation thresholds for hot liquids.

-

Include tactile zones for slip resistance in wet conditions.

-

Design modular inserts for accessibility retrofit.

Interpreting the ergonomic design guidelines above helps teams prioritize testing. Loop clearance testing across small to large hand spans reduces false starts. Rounded fillets and ergonomic fillets minimize contact stress and improve comfort during repeated lifts. Aligning handle angle with pouring motion reduces wrist torque and spillage risk in lab pours. Thermal insulation thresholds protect skin during typical steep cycles. Tactile zones enable secure handling in wet or soapy conditions. Modular inserts expand accessibility without large tooling costs. Teams that sequence guidelines into prototyping sprints often achieve stable, user-validated geometries faster.

Manufacturing Constraints and Production-Ready Decisions

Manufacturing choices shape which ergonomic forms are feasible at scale. Slip casting offers subtle curvature options for ceramics but limits undercut depth. Pressed and stamped metal handles allow thin profiles but require polishing to remove stress risers. Injection molding supports complex internal cavities for insulated handles. Join methods like adhesive bonding or mechanical interlocks determine longevity under thermal cycling. Tolerances for dimensional stability must be realistic to avoid assembly issues. Working with production engineers early clarifies trade-offs between ideal ergonomics and feasible tooling. Clear DFM feedback loops prevent costly rework once designs move to volume production.

Comparative Table: Handle Types, Materials, and Best Uses

| Handle Type | Common Material | Best Use Case |

| Loop Handle | Ceramic, porcelain | Traditional tea service |

| Thumbrest Handle | Stoneware, composite | Precision pouring |

| Overmold Grip | Silicone over polymer | Accessibility and safety |

Using the comparative table helps procurement and design teams match materials to intended use. Loop handles suit elegant tea rituals where visual balance matters. Thumbrest handles improve precision and control for tasting sessions. Overmold grips prioritize safety and work well in institutional settings. Each row flags production considerations and typical finishing steps to smooth factory handoff. Teams should cross-reference the table with user study results to finalize choices for targeted markets and demographics.

Testing Protocols: Objective and Subjective Measures

Testing combines objective metrics with subjective user reports for handle validation. Objective tests include lift torque, slip force, and thermal transfer. Record force-to-lift data across various liquid volumes. Measure slip resistance under wet and soapy conditions using standardized tribometers. Thermal sensors monitor surface temperature over repeated steep cycles. Subjective surveys capture comfort, perceived stability, and aesthetic satisfaction. Use mixed cohorts to include elders, dexterity-limited users, and baristas. Statistical analysis of results highlights significant differences between prototypes. Iterative testing confirms that ergonomic tweaks translate into meaningful user benefits.

Regulations, Safety Standards, and Compliance

Ergonomic Design of Teacup Handles intersects with safety and material regulations across markets. Food-contact approvals require certified glazes and coating materials. Thermal limits must align with consumer safety guidance for hot beverages. Accessibility standards vary and reward inclusive design features. Manufacturers should document material certificates, test reports, and batch records for audits. For export, ensure compliance with destination country norms for ceramic imports. Early regulatory engagement reduces last-minute design changes or market entry delays. Solid compliance practices also support stronger brand trust and fewer product recalls.

Final Recommendations and Implementation Roadmap

Prioritize human-centered research and iterative prototyping early in the program. Define target hand spans and set clearance tolerances based on measured cohorts. Choose materials that meet both tactile and thermal needs for the intended market. Prototype with rapid methods, then validate with mixed-user groups under realistic conditions. Integrate DFM reviews to ensure ergonomics translate into manufacturable parts. Maintain clear documentation of test protocols and acceptance criteria. Finally, plan for accessible retrofit options to expand product reach. Applying this roadmap helps teams deliver teacups that balance beauty, safety, and everyday comfort.

Frequently Asked Questions

What are the most common ergonomic failures in teacup handle design?

Common failures include inadequate loop clearance that causes finger compression. Designers sometimes ignore wrist angle in pouring, raising torque and spillage risk. Overly thin contact edges create pressure hotspots on finger pads. Glossy finishes without tactile zones lead to slippage when wet. Thermal conduction through thin handles can burn users during hot steep cycles. Manufacturing variability can make a good prototype feel different in volume production. Addressing these issues requires early testing and close DFM collaboration. Proactive sampling catches most ergonomic pitfalls before they reach customers.

How should teams measure handle usability across populations?

Start with anthropometric mapping across intended user groups to set baseline clearances. Use timed lift-and-pour tasks with instrumented cups to capture torque and lift metrics. Complement objective data with Likert-scale comfort surveys after repeated use. Include special cohorts such as older adults and people with reduced grip strength. Perform slip-resistance testing in both dry and wet states. Run thermal transfer tests during consecutive steep cycles to capture heat accumulation. Triangulate findings to declare pass/fail criteria for design iterations. This mixed-methods approach yields robust, generalizable conclusions for ergonomic design.

Can existing teacups be retrofitted for better ergonomics without full redesign?

Yes, many existing cups can take retrofit solutions that improve comfort. Overmolded silicone sleeves add grip and insulation to simple loop handles. Removable thumbrest clips provide better control for precise pouring. Add-on handle extenders increase loop clearance for larger hands. Non-permanent textured wraps improve slip resistance in wet conditions. Modular inserts can convert narrow loops to ergonomic profiles for specific populations. Retrofitting allows manufacturers and retailers to offer upgraded ergonomics without scrapping current inventory. Evaluate adhesion, cleaning, and safety implications before rolling out retrofit accessories at scale.