The making process of Tenmoku is very complicated. It has many different steps. Every step requires a skilled craftsman. A craftsman must have much experience. The final result is a beautiful piece. This article will explain the making process of Tenmoku. It starts from the raw clay. It ends with the finished ceramic bowl. Every detail is crucial for success.

The Making Process of Tenmoku: Clay Selection

The first step is clay selection. It is a very important part of the process. Jian Zhan clay must have a lot of iron. Its glaze also needs a high iron content. During the Song Dynasty, other kilns tried to copy Jian Zhan. Their clay did not have enough iron. This is why their copies were not as good. The right clay is the foundation. It gives the bowl its unique color. This is the first secret to a perfect bowl. The iron content helps create the beautiful patterns. It is what makes the bowls so special.

Preparing the Clay for Making Tenmoku

The raw clay must be prepared. It is first crushed into a fine powder. This is done with a machine. Then, the powder is washed. It is put through a sieve. This removes all impurities. The goal is to get a smooth texture. The clay is then put in a slurry tank. It is kept at a certain humidity. This makes it ready for the next step. This process makes the mud dense. It also makes it uniformly humid. This helps prevent cracking later on.

Aging and Kneading the Clay

The clay is now ready for aging. This step is called "Chen Fu." The clay is placed in a room. It is away from sunlight and air. A certain temperature and humidity are maintained. This process can take a long time. It helps the clay become more plastic. The clay is then kneaded. This removes air and impurities. It makes the mud dense. It also makes the humidity uniform. This makes the clay easier to form. It also stops it from cracking later.

Shaping the Pottery Piece

Shaping is a key step. It can be done by hand. It can also be done with a machine. The craftsman must be very precise. The shape of the bowl is important. It must be balanced. The sides must be even. This ensures a good result. A good shape holds the glaze well. It also feels good in your hands. A good piece starts with a good form. The shaping process is a form of art. It requires years of practice to master.

The First Kiln Firing of Tenmoku Pottery

The first firing is for the unglazed clay. This process is called bisque firing. It is done to increase the clay's strength. It also makes the clay porous. This helps the glaze stick later. It also removes fragile pieces in advance. This reduces the risk of cracking in the final firing. The clay is now ready for the next step. It is now ready for the glaze. This is the stage where the piece gets its first taste of heat.

Blending the Glaze for The Making Process of Tenmoku

The glaze is a big secret. It is a very special blend. The ancient method uses natural iron ore. It also uses plant ash. These materials create beautiful colors. They form mysterious crystals. The secret is simple materials. They create a wonderful result. The glaze is what gives the bowl its unique look. It is what makes each bowl different. This blend is what makes the final patterns appear.

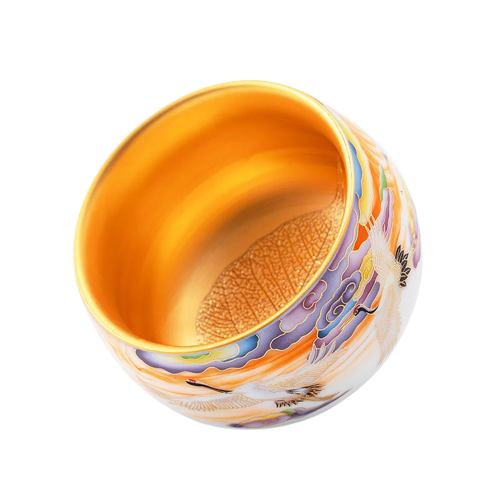

Glazing the Tenmoku Bowl

Glazing requires great skill. The Tenmoku bowl has a half-glazed look. The glaze is poured over the bowl. An ancient glaze line helps control the range. The glaze must be just right. If it is too thin, crystals cannot grow. If it is too thick, the glaze can stick. It is a very delicate balance. A master potter can get it right. This half-glazed style is a clear sign. It is a sign of a traditional Tenmoku bowl.

The Second Kiln Firing of Tenmoku

The second firing is the most important part. The bowl is placed in the kiln. A layer of powder is on the bottom. This prevents sticking. The master controls the fire. They manage the reduction and temperature. The final color depends on this step. The master must stay focused. A mistake can ruin the piece. This is where the magic truly happens. A master watches the kiln very closely.

The Finishing Process of Tenmoku

The kiln creates many defective goods. They must be thrown away. Only perfect pieces can be sold. These pieces are very special. They are a treasure. They are a sign of great skill. Each bowl is a work of art. It is a testament to the master. It is the end of a long journey. The craftsman must inspect each piece. They look for cracks, drips, or other flaws. Only a few will pass this test.

The Role of Reduction in the Tenmoku Bowl Production

Reduction is very important for the final look. It happens in the kiln. It means there is not enough oxygen. The potter controls the air flow. This creates a specific atmosphere. The lack of oxygen changes the iron in the glaze. The iron changes its chemical form. This changes the color and the crystal patterns. For example, a proper reduction can turn a simple glaze into a deep black. This is what makes the Tenmoku bowl so special.

Why the Uniqueness of The Making Process of Tenmoku Matters

The uniqueness of each bowl is important. It comes from the many variables. The clay, the glaze, the kiln. The temperature, the atmosphere, the cooling. The master cannot control everything. The final result is a gift. It is a gift from the fire. It is a gift from nature. This is why the bowls are so valuable. Each one is a unique work of art.

The Tools Used in the Making Process of Tenmoku

Many tools are used for this work. They help the craftsman. They make the process easier. The tools are often simple. They are also very effective.

-

Kiln: This is a large oven. It is used to fire the pottery. It must reach very high temperatures. It is the heart of the process.

-

Glaze Bucket: This is a large container. It holds the liquid glaze. The bowls are dipped into it. It is used to apply the glaze evenly.

-

Tongs: These are for holding the bowls. They keep the craftsman safe. They also allow for a steady grip. This prevents unwanted fingerprints.

-

Sieve: This is for straining the glaze. It removes any lumps. It makes the glaze very smooth. This is important for a good finish.

-

Turning Wheel: This is for shaping the clay. It spins the clay very fast. The craftsman uses their hands. They shape the clay into a bowl.

Using the right tools is very important. It ensures a good result. It helps the craftsman in their work. It also makes the final piece better.

| Step | Purpose | Challenges |

|---|---|---|

| Clay selection | Ensure high iron content | Sourcing the right materials |

| Kneading | Remove air, make mud dense | Requires physical strength and skill |

| Glazing | Apply an even coat | Preventing drips and cracks |

| Kiln firing | Create glaze crystals | Controlling temperature and reduction |

| Finishing | Inspect and discard defects | High rate of failure and waste |

This table shows the steps in the making process of Tenmoku. It shows the purpose of each step. It also shows the challenges involved. The table highlights the difficulty. It shows why this art is so hard. It takes a master to get it right. It shows why the final product is so prized. It takes a lot of effort and time to create a perfect piece.

Frequently Asked Questions

1. How do you prevent the glaze from sticking to the kiln shelf?

Preventing sticking is a very important part of the process. Glaze can become very liquid when it is hot. If it drips, it can stick to the kiln shelf. This will ruin the bowl. The most common method is to leave the bottom of the bowl unglazed. This is a clear sign of a traditional Tenmoku bowl. The glaze line stops just before the foot of the bowl. This keeps the glaze from dripping. Another method is to put a layer of alumina powder on the kiln shelf. The powder acts as a barrier. It keeps the glaze from sticking to the shelf. This is a simple but effective method. Without this step, the master's work would be wasted. A master must pay close attention. It ensures the bowl's bottom is clean. This allows it to stand properly.

2. Why is the iron content in the clay and glaze so important for a Tenmoku bowl?

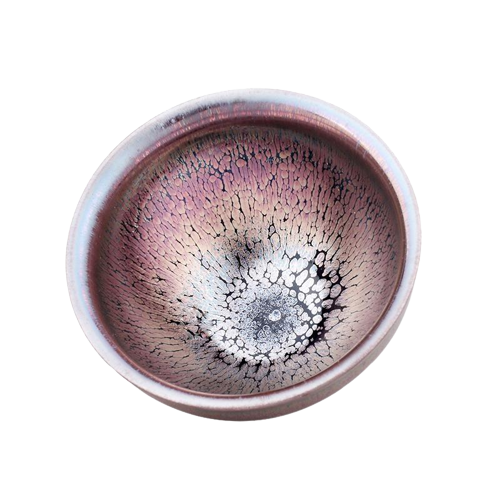

The iron content is critical for a Tenmoku bowl. The iron is what creates the famous patterns. These patterns are called crystalline glazes. When the bowl is fired, the iron in the glaze melts. It then separates from the other materials. As the bowl cools, the iron forms crystals. These crystals create the beautiful designs. For example, they can look like "hare's fur" or "oil spots." The more iron in the glaze, the more dramatic the crystals can be. The clay also needs high iron content. This helps the glaze and the clay work together. It also affects the final color of the bowl. A clay with high iron can look dark. This provides a great background for the glaze. Without high iron, a Tenmoku bowl would not have these unique patterns.

3. What is the role of "reduction" in the making of a Tenmoku bowl?

Reduction is very important for the final look. Reduction happens in the kiln. It means there is not enough oxygen. The potter controls the air flow. This creates a specific atmosphere. The lack of oxygen changes the iron in the glaze. The iron changes its chemical form. This changes the color and the crystal patterns. For example, a proper reduction can turn a simple glaze into a deep black. It can also make the crystals more vivid. If there is too much oxygen, the glaze will not get the right color. The master must be very careful. They must control the fire very well. This is what makes the Tenmoku bowl so special. It is a delicate art. The final color is a result of this perfect control. It shows the master's skill.